CFD Simulation – Methods and Applications

Despite being a cutting edge technology that is still not well known in Brazil, we welcome you to understand more about the idea and use of computational fluid dynamics. Generally, it is used in industrial processes and it can be the decisive tool in changing the conception of any production area and its strategic role, as well as being the factor that will transform businesses’ results – mainly with productivity gains and cost reduction.

Today, we will elaborate more on this topic, pointing out some fundamental aspects of this method to be possible. Read more about CFD simulations and its methods down below to learn how this technology can be the turning point in your business.

What is Computational Fluid Dynamics (CFD)?

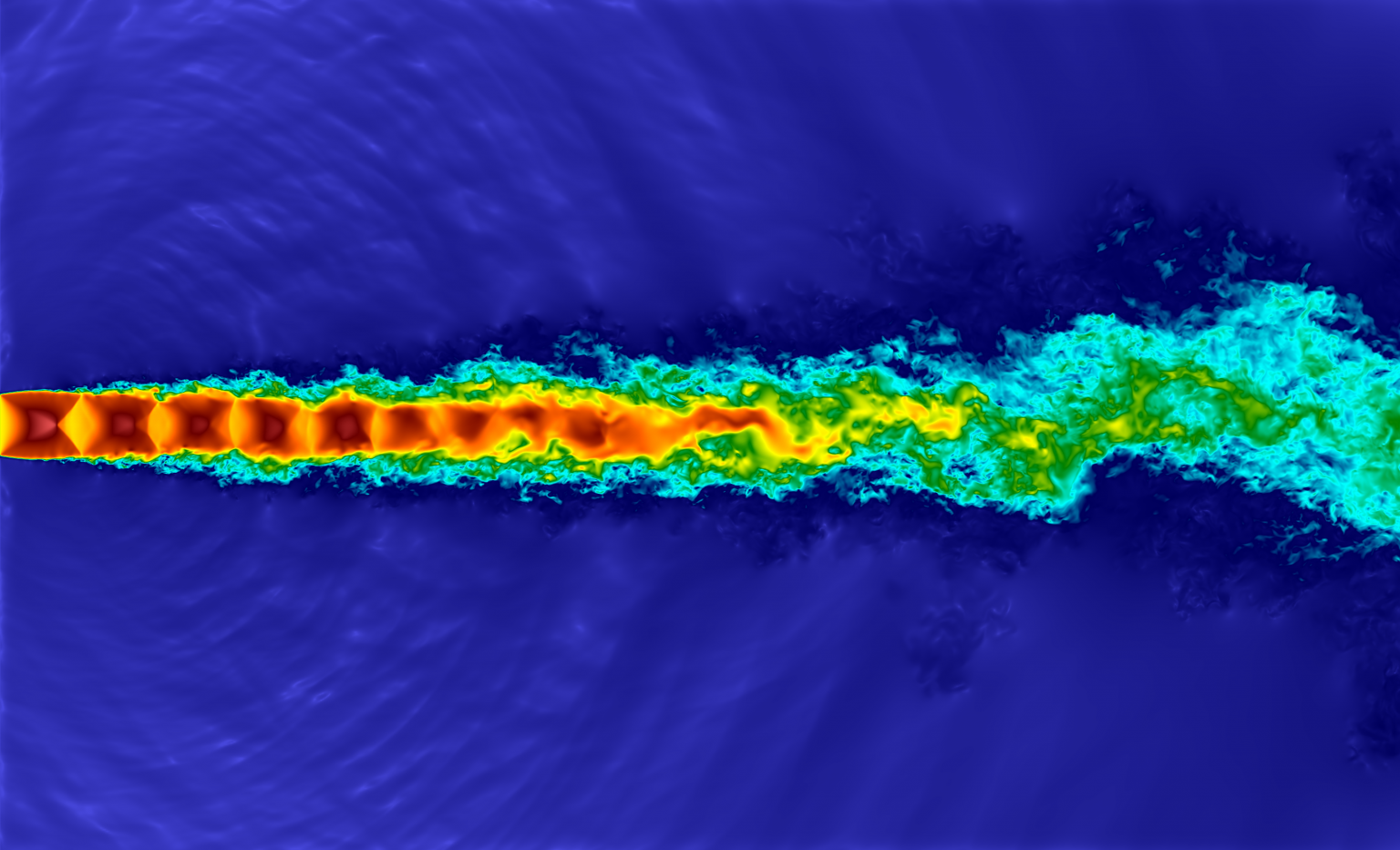

Computational Fluid Dynamics (CFD) is a tool capable of analyzing the behavior of liquid and/or gaseous fluids in different industry applications. Through fluids analysis focused on thermal velocity, concentration, and pressure, CFD simulations can demonstrate in a 3D environment the behavior of these variables and where possible imbalances that generate losses may be occurring.

Here are some examples of industrial processes that can be analyzed:

– Controlled Atmosphere Environments

– Mixers and Agitators

– Valves and Pipes

– Heat exchangers

– Security and environment

As mentioned above, it is possible to suggest actions to improve the performance of industrial processes directly and decisively. Computer numerical simulation is a technology currently applied in industries that seek high performance in their processes and products, in which quality is a competitive differential.

Benefits:

Some of the advantages generated by CFD technology are related to the ability to generate results without intervening in the process to verify different solutions and scenarios, such as trials and errors that can stop production, as well as operational risks along with production losses.

Adding the CFD technology to industrial processes is a market trend that is fully aligned with the Industry 4.0 concept. The use of this technology can generate value by improving quality and reducing costs to industrial processes. Learn more about its application in different industries here.