Sanitation: 3D Computational Simulation applied to the treatment of water phases.

The water treatment through the conventional process goes through several phases and each one requires a strict physical-chemical control. For example, in a company like SABESP, there are 9 stages in the process, where are treated more than 119 thousand liters of water per second.

In this context, we are dealing with a very high flow rate that requires tools and solutions that are able to optimize the process, decrease the cost, increase performance and mitigate losses.

A 3D computer simulation is a solution used in the engineering segment that provides these resources to companies in the field of basic sanitation. Below are three examples of possible applications for this segment:

Aerobic and Anaerobic Digesters

Biological wastewater treatment uses naturally-occurring microorganisms to feed on complex organic matter, converting them into simpler substances. This type of treatment is split in anaerobic and aerobic treatment.

Unlike anaerobic treatment, which makes use of bacteria that do not use oxygen in their biochemical processes, aerobic treatment uses microorganisms that degrade organic into inorganic substances through oxidative processes.

In aerobic biological processes like these, there are effluents that need to be in a condition of controlled temperature, pH and oxygenation.

While in anaerobic processes, these same physical-chemical conditions need to be controlled, in addition to the need to monitor the emission of odors in the treatment system. Beyond that, professionals need to be concerned about the health of the final consumer and to be aware of environmental issues, since gases Methane and Carbon Dioxide (by-products of the process) intensify the greenhouse effect.

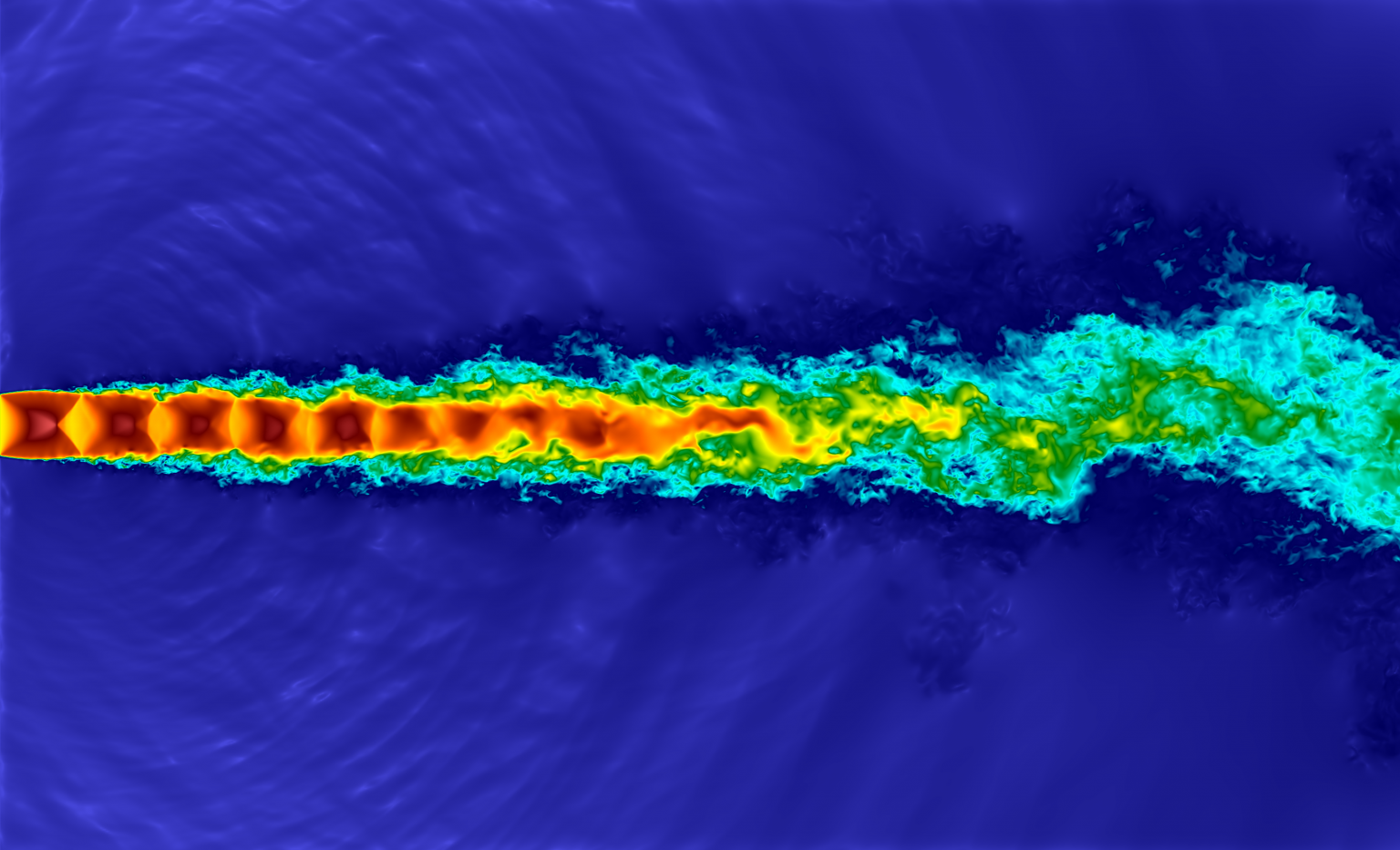

With 3D computational simulation is possible to study fluid’s behavior in the biodigesters, evaluating the flow pattern, heat, and mass transfer, which contributes to decision making that brings improvements in the process and in energy efficiency.

Tanks

Mixing tanks, which are also widely used in the food industry, are equipment present in several stages of the water treatment process. For example, in the chemical addition step, where the collected drained water is mixed with aluminum sulfate AI2(SO4)3 and sodium hydroxide Ca(OH)2

Another stage where this equipment is normally used is in the filtration stage. At this point in the process, it is important to separate sediments, such as sand, gravel, boulders and active carbon.

Prototyping is able to help companies in projects for the assembly of sanitation stations with this type of equipment and in the evaluation of the efficiency in the liquid-solid mixing and separation process.

Flocculation

Finally, flocculation is a chemical water treatment technique that aid to decant small solid particles through aggregation in the flocculator, where chemical substances called coagulants are added to the water.

Generally, flocculation occurs before the process of decanting insoluble solid impurities in sedimentation tanks.

With the study of applied computational fluid dynamics with focus on flocculation process it is possible to evaluate the fluid dynamics and heat transfer behavior that impact the neutralization mechanisms of these colloidal impurities, as well as the agglutination of these particles.

Do you want to know how we can help you with water treatment in your company? Contact us for an evaluation in your process.